Precision coating removal

Most wires consist of the wire itself wrapped in a polymer coating. So what if you need to use a fine wire without the insulation in a medical device, for example? Lasers offer a way to de-coat these wires without interfering with the substrate – in this case, the wire(s). Learn more about our custom solutions here.

How it works

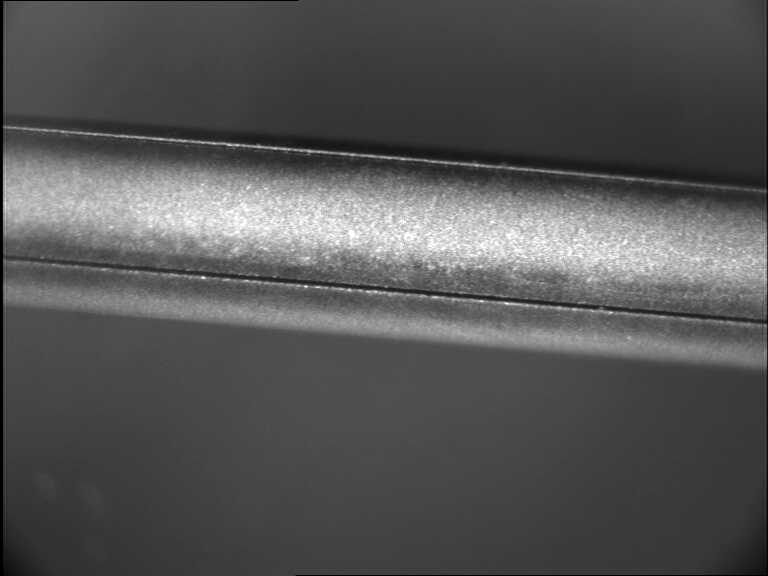

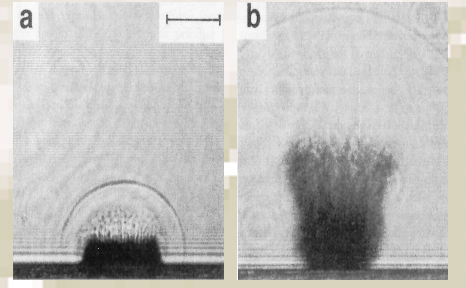

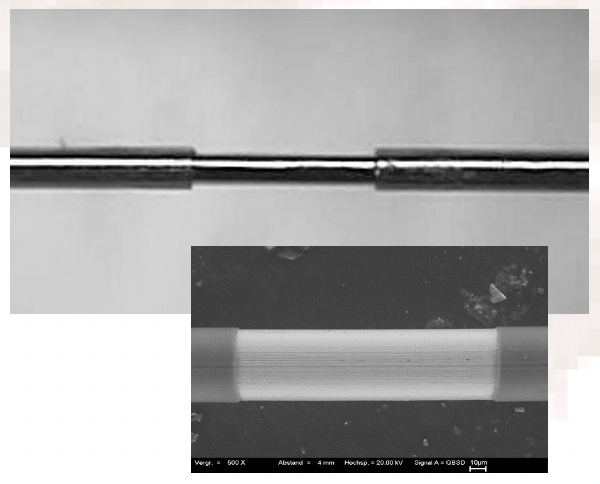

The polymer coating on the wires absorbs the laser light and is instantly ablated (deconstructed). The metal of the wire reflects the light and is unharmed during the process. Compared with other techniques such as mechanical or chemical stripping, it’s a much more controlled process. The conductor wire remains completely safe from harm, and smaller wires may be used.

Suitable for fine applications

There are some industries where only the finest wires will do. Medical devices and electric consumables are good examples. Wires in these applications could be less than 20 microns in diameter. Laser wire stripping ensures the wire itself remains unharmed, removing the risk of any defects. The polymer coating is removed entirely, leaving no residue. And you get reproducible results with reduced waste and cost.

The technical support from the team at Raymax is second to none. They are always available to assist with any problem.

Making the impossible possible

Without this technology, certain innovations simply would not be possible. At this very fine level (20 microns or half the width of a human hair), any tampering with a wire would risk breaking or damaging it.

Laser stripping of complex forms, such as twisted or coiled wire, and partial removal is also made possible. The only trick is that the photons need to see the insulation to blow it away. Talk to the laser physics experts at Raymax to find out if your application could be possible.

Proof of concept

Are you a start-up or manufacturer that thinks this technology could work for you? We have lasers with this capability in our laboratory. Before we talk to you about purchasing any laser equipment, we test material interaction with different lasers to check it works. Failure to validate a concept can lead to costly mistakes. Use our laser physics expertise to help find the right laser solution.

Why Raymax?

We make laser light work for you. We’ve spent over 30 years demonstrating what’s possible with lasers. In doing so, we’ve helped modernise Australian and New Zealand industries. You’ll be working with a team of physicists and factory-trained engineers—leaders in the supply of laser solutions and photonics equipment. We’re experts in material interaction research. Wherever possible, you’ll be introduced to new technology that can improve operation in ways you might not have imagined possible.

Speak to an expert

Enter your details and we’ll get in touch to discuss your needs.Book a Consultation

Contact Us

(02) 9979 7646

Visit Us

37/5 Ponderosa Parade Warriewood NSW 2102