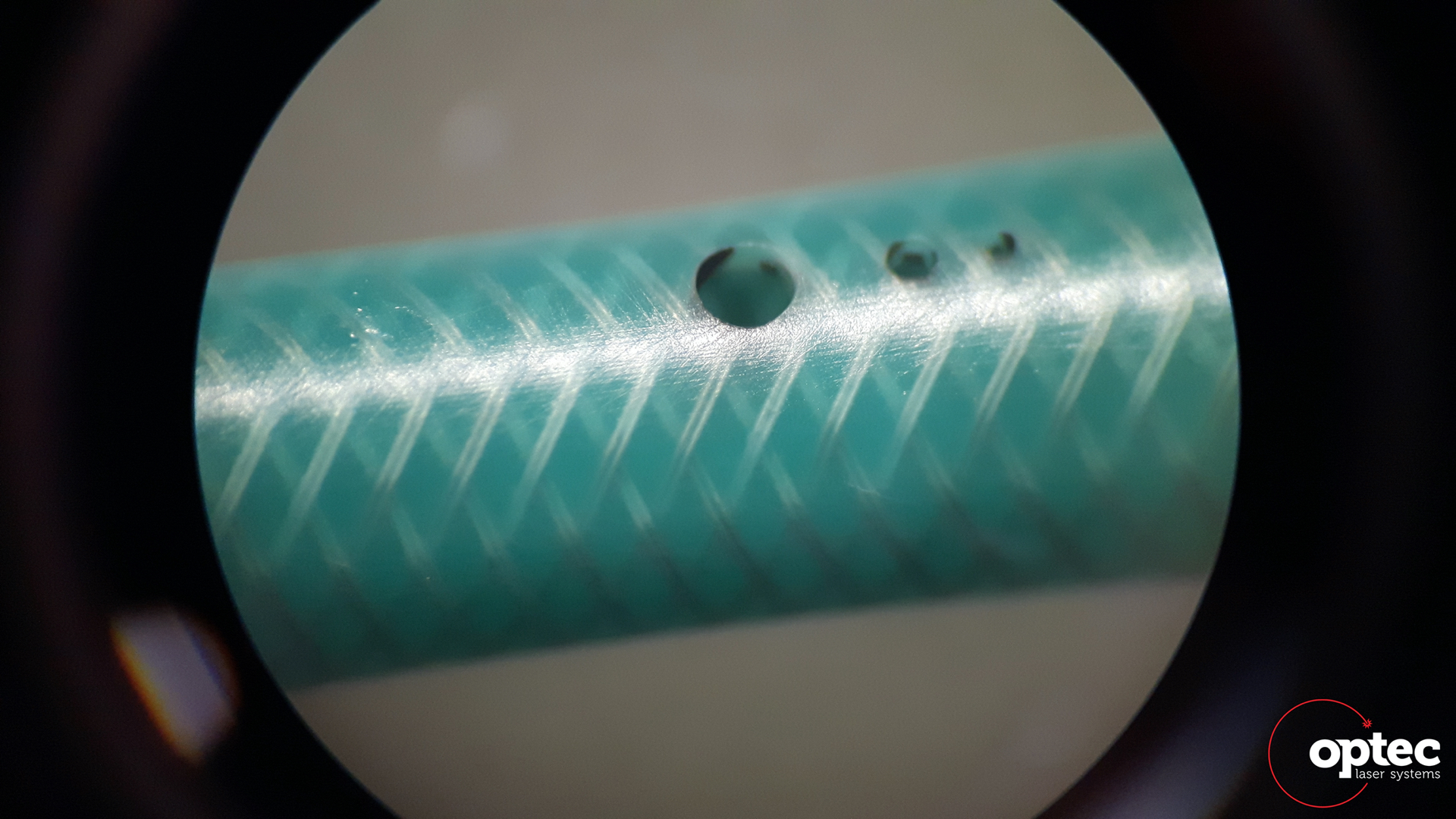

Metal laser ablation process

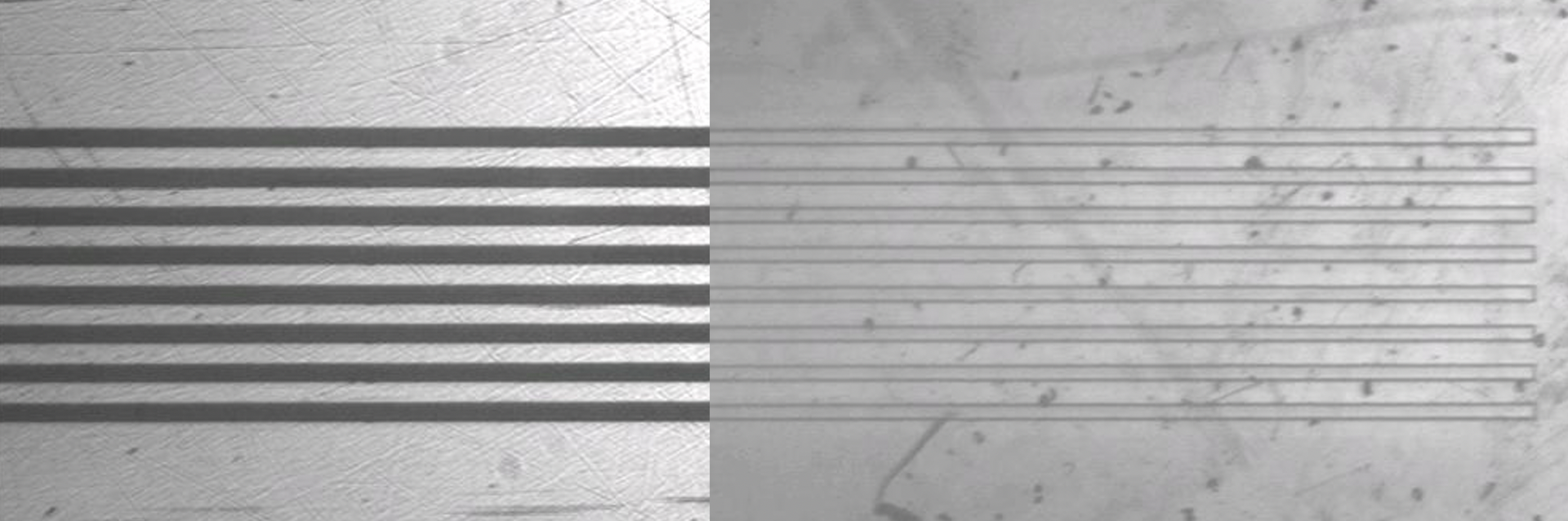

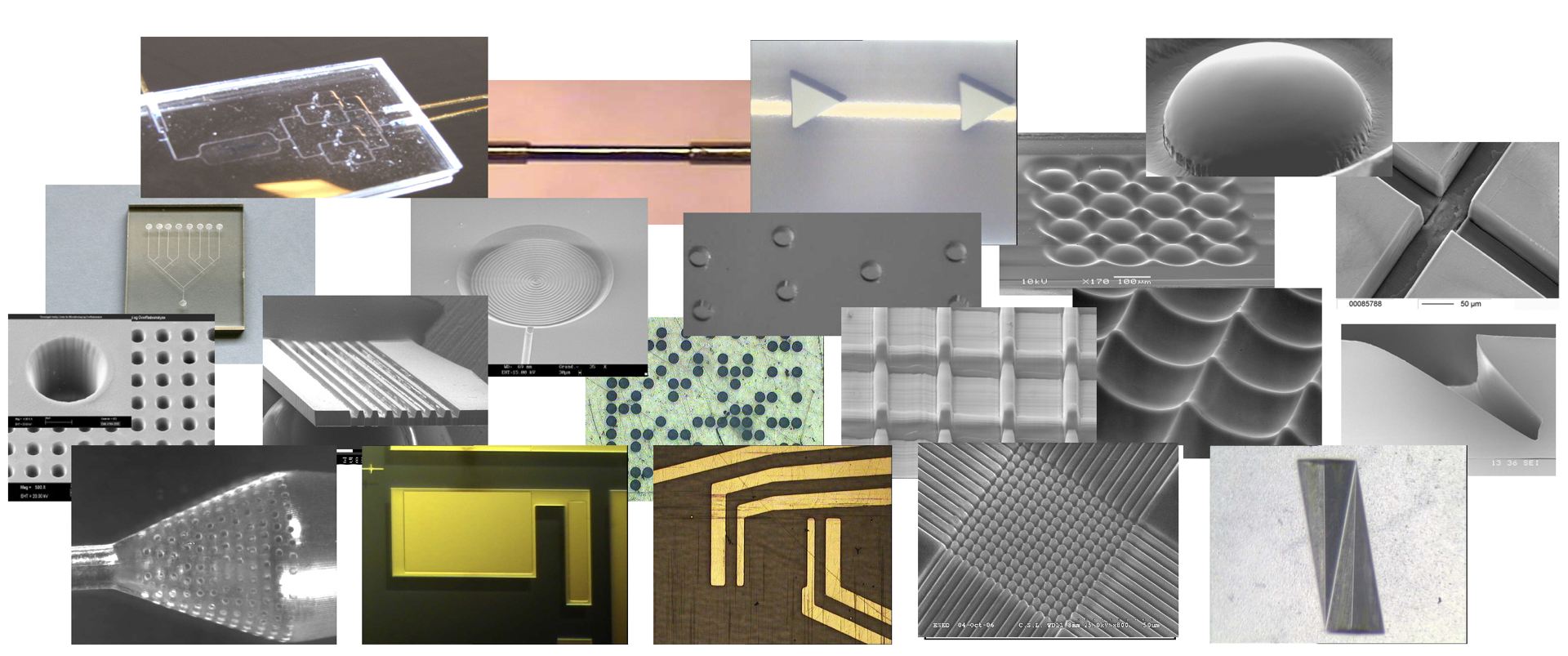

Laser ablation of this kind removes metals from a polymer, glass or ceramic substrate. Depths of less than a micron are blown away in a single pulse. Laser ablation is used to create complex and custom patterns on a microscopic scale. Some other laser systems can create the same patterns but, unfortunately, also eat into the material underneath. Understanding the way the materials interact with different sources of light ensures your success.

Fit for purpose

Laser ablation is highly favoured in medical manufacturing. At this miniature size, the acceptable tolerance (margin for error) is extremely close. There’s simply no other way to create the microscopic parts required with such precision. It’s also zero contact. The metal is ablated without other machinery physically touching it. Instead, a precise and short pulse of light is used. Some current applications include creating single-use conductive tracks and catheter tip shaping.

Faster prototyping & production

In a manufacturing environment, it’s essential for things to move quickly. With laser ablation, large areas can be processed accurately and at speed. This works two ways. You can make lots of tiny things quickly or process larger surface areas equally fast. Features of a few microns width can be written over large areas. This type of micromachining is a facilitator of industry—it makes the impossible possible.

If there’s one thing, I can say to sum up the team at Raymax it is; “Exceptional Customer Service”. Their technical support goes over and above what we would have expected from a supplier. Setting the bar high guys, well done!

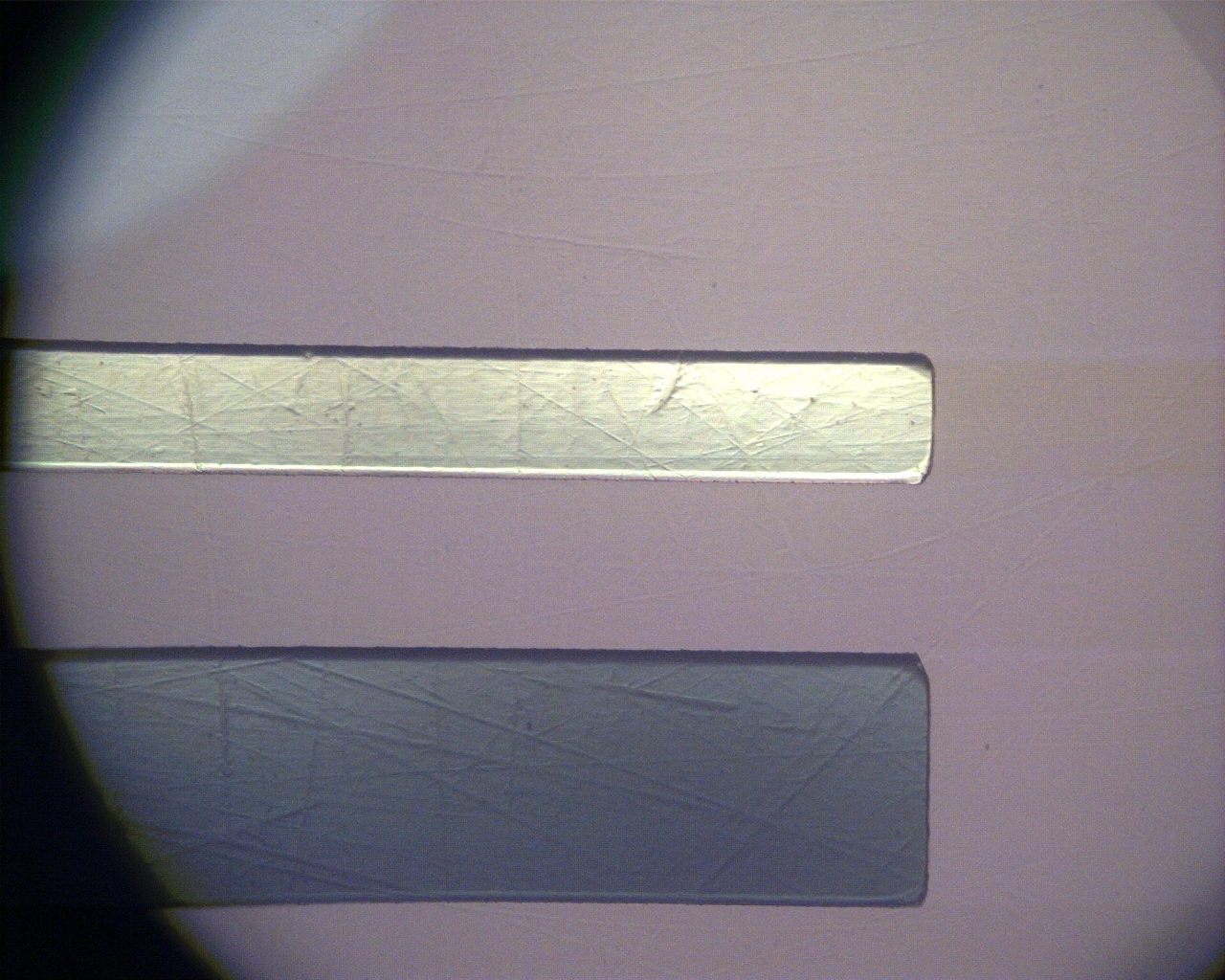

Unaffected substrate

While other lasers can remove metal, they may also cause thermal damage to the material underneath. This is problematic when that material needs to act as a conductor, for example. Laser ablation of metal using ultra-violet (UV) lasers blows away the metal rather than melting it. The substrate is unchanged. Talk to us about incorporating this technology into your manufacturing processes.

Laser Lift Off (LLO)

Laser ablation can be used to remove metal from the top of the substrate. But it’s also possible to push entire sheets of very thin metal from a substrate using excimer lasers. This process is called Laser Lift Off (LLO). The UV wavelengths create a plasma at the interface of the materials. They debond. And the substrate remains underneath as a support to the very fine layer of metal for further processing.

Proof of concept

Femtosecond, picosecond and nanosecond pulse length lasers of different wavelengths perform precision ablation of metals. Contact the laser physicists at Raymax to find out if this process is right for your requirements. We have the ability and expertise to perform definitive tests to define how the systems could work for you.

Why Raymax?

We make laser light work for you. We’ve spent over 30 years demonstrating what’s possible with lasers. In doing so, we’ve helped modernise Australian and New Zealand industries. You’ll be working with a team of physicists and factory-trained engineers—leaders in the supply of laser solutions and photonics equipment. We’re experts in material interaction research. Wherever possible, you’ll be introduced to new technology that can improve operation in ways you might not have imagined possible.

Speak to an expert

Enter your details and we’ll get in touch to discuss your needs.Book a Consultation

Contact Us

(02) 9979 7646

Visit Us

37/5 Ponderosa Parade Warriewood NSW 2102