Report from Modern Manufacturing Expo

This first-time exhibition at Sydney Showground featured companies with products to encourage innovation in manufacturing. Canvassing their ideas were several universities ready to talk about their latest projects and steps in skills development. Parallel seminars were held over the two days that covered a range of topics in the two locations of the Expert Arena and Smart Manufacturing.

As an exhibitor, Raymax had a booth to display finished product and samples of laser output particularly welding. With our large WAAM sample attracting a great deal of interest! We also had a video providing details of our complete product range with explanations and usage demonstrations.

The key products featured at Raymax booth:

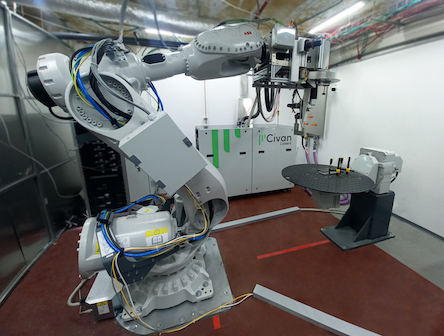

On display were samples of welding dissimilar metals, welding different thicknesses of metals, even welding copper, all from the CIVAN high power laser system. “Can I weld dissimilar materials?” was a frequent question during the exhibition making it evident industry is moving to innovate production. A sophisticated and proven system, CIVAN provides four advantages to welding: exceptional beam shaping, shape frequency, beam sequencing and focus steering. The CIVAN laser is suitable for welding, cutting, metal AM and drilling.

Wire Arc Additive Manufacturing, housed in a Mobile Smart Factory

The sample of WAAM was produced in the Mobile Smart Factory. This Wire Arc Additive Manufacturing system is housed in two shipping containers ready to be located in a car park or beside a working mine site! Included is an ‘office’ space where a broken or worn part can be scanned using the available software. Or, if required a new part can be designed. The design is then built using WAAM technology, on completion the part can then be machined to a finished standard. All this occurs in one location – in the two shipping containers.

The smooth sample of a welding join on stainless steel was closely inspected with visitors exclaiming they had never seen such great finish! Other examples from Laserline included braising and welding different materials all with reduced spatter and clean finishes. Cédric and John discussed the new LDMblue laser from Laserline with some very interested parties. The blue diode laser revolutionizes the processing of copper, gold, and other highly reflective metals, and opens up new application opportunities such as heat conduction welding of thin copper foils.