Commercial Challenge

Micro structuring flexibility is the fundamental requirement of the Australian National Fabrication Facility (ANFF) node based at the University of South Australia (UniSA). Their open-access facility specialises in microfluidics, organic electronics, biomaterials and novel semiconduction characterisation.

UniSA required direct laser writing capability on the micron scale to support their academic and industrial research base.

The ANFF-SA node routine uses their Dilase 650 system to support the cutting-edge research conducted within the facility. The ongoing relationship with Raymax and Kloe benefits further new capability developments.

The Solution

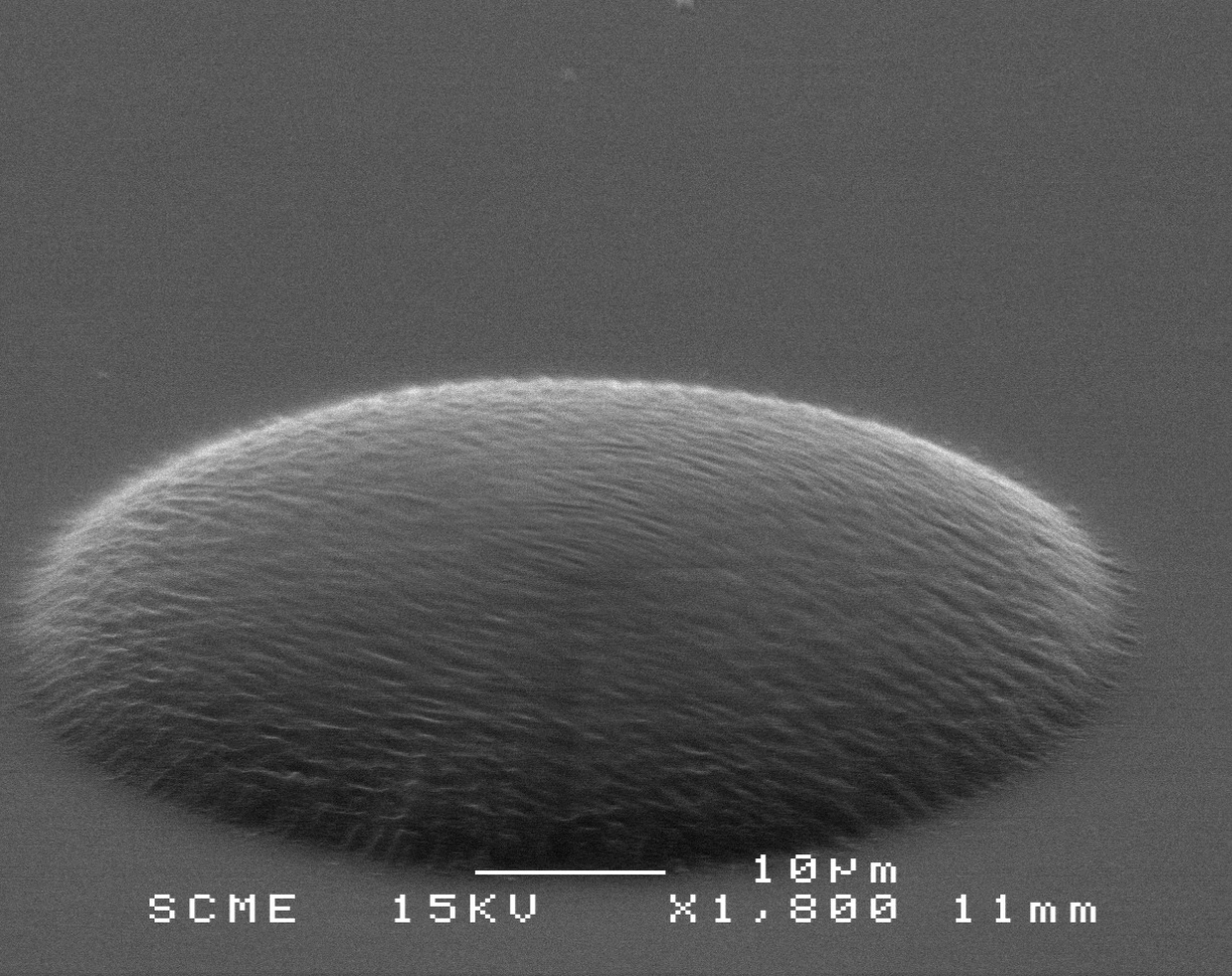

An extensive evaluation of the lithography machines available led the ANFF group to choose the direct laser writing and high aspect ratio capability of the Kloe DiLase 650 for their requirements.

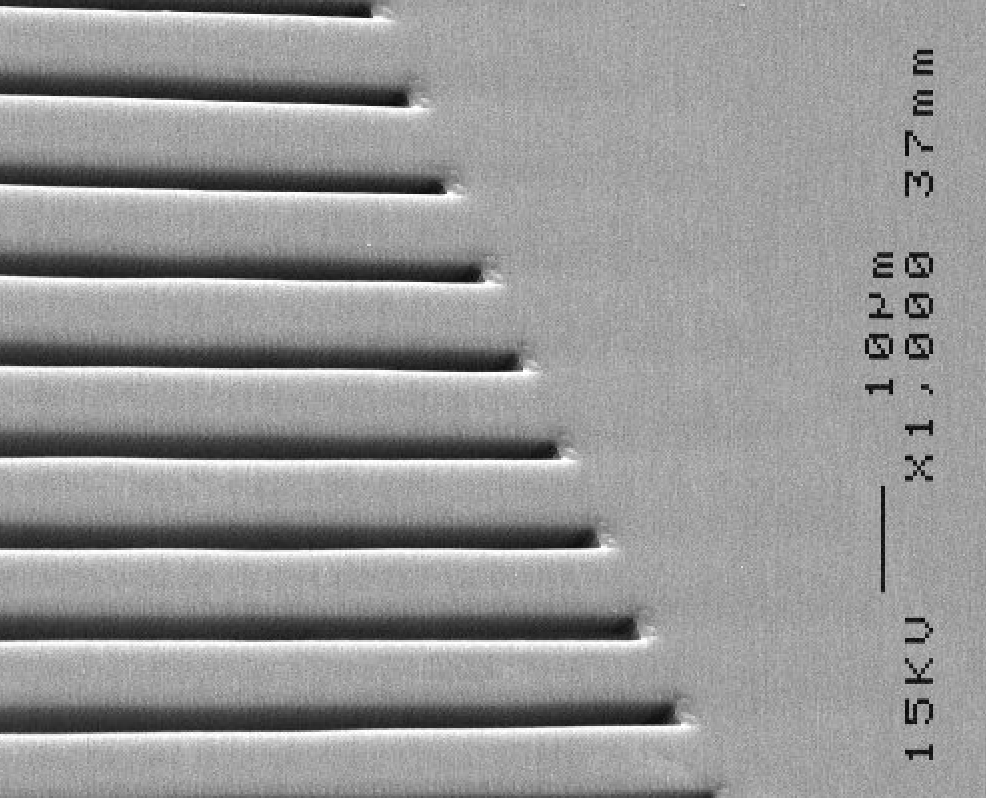

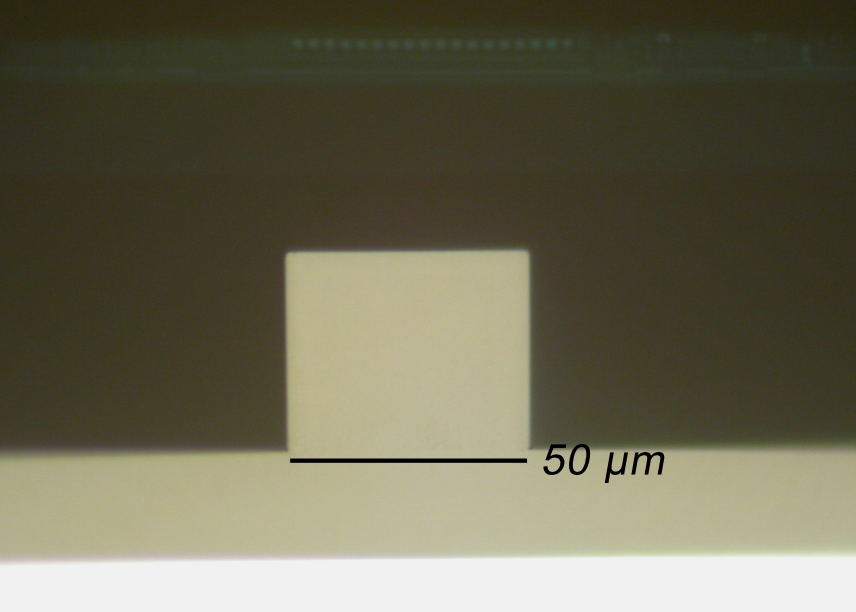

The dual laser and dual wavelengths of the Kloe direct-write UV technology allow for the selection of beam sizes from 0.5 microns to 100 microns in a range of different photoresists. This flexibility is the principal reason they chose the laser machine.

Results

The Australian National Fabrication Facility (ANFF)-SA node routinely uses its Raymax supplied Kloe Dilase 650 system. The flexibility is offered in different photoresists and dual wavelength. Varying beam sizes from 0.5 microns to 100 microns then support cutting-edge research conducted within the University of South Australia. ANFF is pleased with the continued relationships with Raymax and Kloe.

Why Raymax

We make laser light work for you. We’ve spent over 30 years demonstrating what’s possible with lasers. In doing so, we’ve helped modernise Australian and New Zealand industries. You’ll be working with a team of physicists and factory-trained engineers—leaders in the supply of laser solutions and photonics equipment. We’re experts in material interaction research. Wherever possible, you’ll be introduced to new technology that can improve operation in ways you might not have imagined possible.